Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Auto Glass Laminating Autoclave With ASME U stamp ISO certificate or CE certificate

Glass Autoclave (Series of SN-BGF-J)

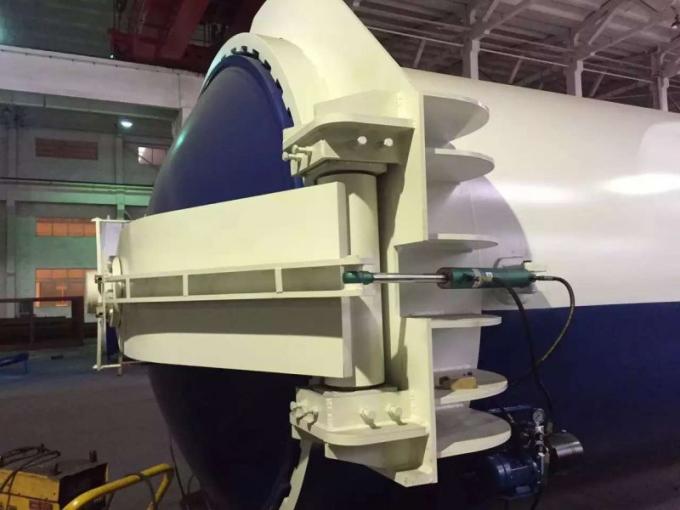

Structure and configuration of autoclave

Autoclave body

Completely according to GB713-2008 "steel pressure vessel" standard design and manufacturing, pressure weld radiographic testing, 100% for equipment provides a powerful guarantee the quality and safety performance. All values are made of SUS304. The autoclave certified to ASME and CE code.

The head

Tooth shape and ellipsoidal head adopts integral forging flange plate, thickness is greater than the kettle body thickness.

The door

Adopt cylinder one way to open the door, have a unique design of walking track, can automatically set and lock. The automation of the device was improved.

Heating element

the medium wave infrared radiation heating pipe, heatingelement is uniformly distributed in the kettle on both sides and bottom, to ensure the kettle in the process of heating in the uniformity of temperature before and after, at the same time to shorten the heating time, achieved the purpose of energy saving.

Thermal insulation material

using high density resin rock wool to internal insulation, the insulation performance is superior to the traditional rock wool; The kettle inside heat loss not easily, especially in heat preservation phase, can be a very good temperature constant, guarantee the machining quality and yield of the product. Other insulation outer part with stainless steel plate and seal, in addition to increasing aesthetic, also played the anti-rust and antifouling functions.

Heat circulation system

inside the kettle on both sides of the layout and the kettle body blowing air inlet connection pipe, uniform processing amount blow holes on the pipeline. In the process of pneumatic compression, as a result of air pressure, blowing holes blow out air, drive the kettle inside air flow, the formation of thermal cycle within the kettle.

Control system

configuration of PLC system, use the color touch screen, theentire process to achieve automatic operation; In the process of work, the pressure and temperature curve display at any time, and the presence of paper recording function, can complete process curve and process parameters of record; In the process of heat booster, with pressure, such as temperature, pressure and temperature control procedures, to ensure the process curve of temperature andpressure by setting a simultaneous, in the process of constant temperature constant pressure and is equipped with automatic temperature and pressure control.

The safety interlock system

on the kettle body is equipped with mechanical safety interlocks, program also set chain security program; Realize the kettle with pressure can't open the door; Super WenChao pressure automatic alarm and overtemperature automatic cooling, overpressure automatic pressure relief, maximum limit to ensure the safety of the operation.

technical specification

| model | inner diameter | length | glass size | design/working pressure | design/working temprature | heating power |

| SN-BGF-G2040 | 2000mm | 4000mm | 1650*4000mm | 1.5/1.3Mpa | 160/150℃ | 108KW |

| SN-BGF-G2650 | 2650mm | 6000mm | 2350*6000mm | 1.5/1.3Mpa | 160/150℃ | 135KW |

| SN-BGF-G2850 | 2850 | 5000 | 2500*5000 | 1.5/1.3Mpa | 160/150℃ | 162KW |

About us

ADVANCED AUTOCLAVE SOLUTION SUPPLIER

my factory is located in hometown of autoclave-Changzhou,Jiangsu,China. It is a leading high-tech enterprise specialized in providing advanced autoclave solutions. Our autoclave with excellent performances are widely used for composite curing,safety glass laminating,PV module encapsulation,wood carbonization.rubber vulcanization,medical waste treatment and so on.

Since the establishment, we have always devoted ourselves to the innovation of autoclave and its control system. Now our Thermal Processing Control(TPC)software,designed according to aviation level,has been able to meet the most strigent technological requirements and the operation performance is safe and stable. Our goal is being the leader of autoclave and its control system.

Customizable specifications to meet customers' different demand;

Meeting various standard like GB150,ASME,PED,AD-2000 and so on. The autoclave comes with relative certificates.

A professional team of engineers working on electrical,mechanical,control and software development departments. The software is updated continuously to meet customers' requirements.

Response time will be shorter than 24 hours and we will try to make the production safe and stable.

Our Services

* your inquiry related to our equipment or price will be replied within 24 hours

* well-trained and experienced staff will answer all your inquiries in English of course

* OEM&ODM projects are highly welcomed

* we have strong R&D team here to help

* Your business relationship will be confidentional to any third party

First-class after-sale service:

* 1 year warranty period,please don't hesitate to contact us if you have any question with the

equipment.

Product Categories : Glass Laminating Autoclave

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.