Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

General feature and working process of the autoclave

1. General feature

Our Autoclave is a sealed pressure vessel which can be heated by a forced convection heating unit, where temperature, pressure and vacuum can be controlled effectively. By means of an advanced design, consisting of a forced convection fun and motor unit, output heating power system can be adjusted 0-100%,proportional control of the pressurization, cooling and exhaust components. It can obtain an uniform temperature and pressure according to the process curve. Temperature is check in heating, keeping, and cooling phase. The heating/cooling gradients can be set by operator. Pressure is adjusted in pressurization, keeping, release phase.

2. Working process

The whole working process of our Autoclave has 17(or more) segments .In each segment, the value of temperature, pressure, vacuum and segment time can be set and monitored by HIM and PC, and the operation process will be realized by our exclusively developed software which is based on PLC control system to ensure the full automatic operation. our Autoclave is suitable for manufacturing various composite materials, and it also can guarantee the perfect product quality.

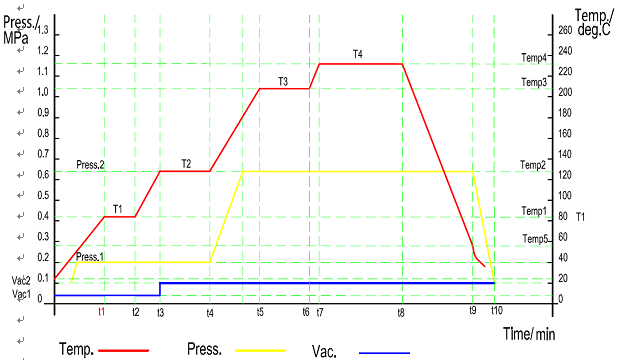

Recipes for example:

Vacu1:minimum vacuum pressure Vac2: maximum vacuum pressure

Press.1: pre-pressure Press.2:final pressure

Temp1:temperature of first segment Temp2: temperature of second segment

Temp3: temperature of third segment Temp4: temperature of forth segment

Temp5: temperature of cooling and release

T1: keeping time of first segment T2:keeping time of second segment

T3: keeping time of third segment T4:keeping time of forth segment

(1) Put the blank of composite materials and the moulds into the vacuum bag, and then put into the autoclave together, finally, start to vacuum, getting the vacuum to the set point: Vacu1

(2) Start heating, Temperature rise to set point:Temp1, at the same time, pressurization, the pressure rise to set point: Press.1, and then starting the first keeping phase , the keeping time is the set point T1.

(3) Completed the first keeping phase, continue to heat, the temperature rise to set point: Temp2, vacuum to Vacu2 or atmospheric pressure, and then began to start the second keeping phase, the keeping time is the set point T2.

(4) Completed the second keeping phase,pressurization, the pressure rise to set point: Press.2.

(5) Continue to heat, temperature rise to set point: Temp3, began to start the third keeping phase, the keeping time is the set point T3.

(6) Completed the third keeping phase,continue to heat,the temperature rise to set point: Temp4,began to start the forth keeping phase, the keeping time is the set point T4.

(7) Completed the forth keeping phase,began to start the cooling stage,Until the temperature dropped to set point:Temp5.

(8) Air release

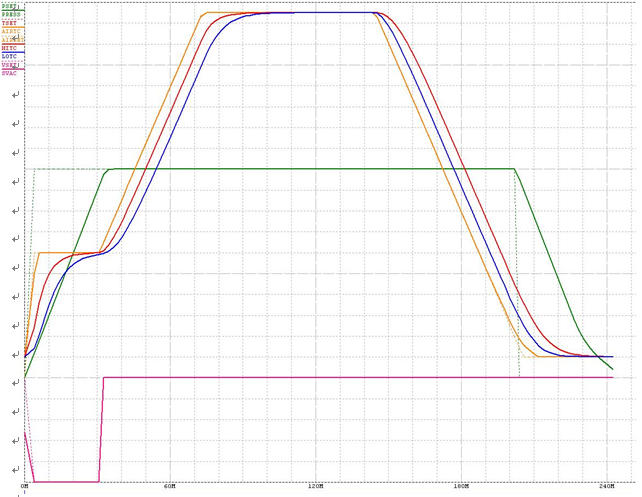

3. Recipe Preview

You can save and choose different recipe.

4. Control System Structure

5. Operation specifications

5-1 Pressure

Ø Pressurization Medium: Nitrogen

Ø Maximum working pressure::1.5Mpa (15bar)

Ø Maximum design pressure:1.6Mpa (16bar)

Ø Pressurization rate: 0-0.6bar/min average rate from 0 bar to max. working pressure.

Ø De-pressurization rate: 0-0.6bar/min average rates from max. working pressure to 0 bar.

5-2 Temperature

Ø Maximum working temperature:250℃

Ø Maximum design temperature of vessel:260℃

Ø Heating rate: 0-3°C/min based on average air temperature from ambient to 250°C and autoclave with 800Kgs PCM and 1500kgs steel.

Ø Cooling rate: 0-3°C/min based on average air temperature from 250°C to 50°C and autoclave with 800Kgs PCM and 1500kgs steel.

5-3 Vacuum

Ø Limit vacuum: ≤-0.098Mpa

Ø Maximum working vacuum:-0.08Mpa

Product Categories : Composite Autoclave

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.