Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 0.6x0.8M electric heating carbon firber autoclave with ASME standard

Place Of Origin: China

Minimum Order Quantity: 1set

Certification: ASME,CE And GB150

Price: 50000USD-100000USD

Packaging Details: According To Client

Delivery Time: 60-90days

Supply Ability: 10/set/per Month

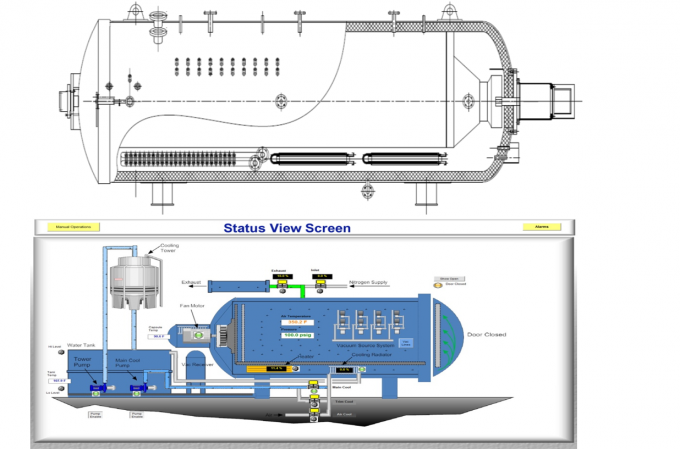

1. Working process

The whole working process of Autoclave has 17 segments .In each segment, the value of temperature, pressure, vacuum and segment time can be set and monitored by HIM and PC, and the operation process will be realized by our exclusively developed software which is based on PLC control system to ensure the full automatic operation.Our Autoclave is suitable for manufacturing various composite materials, and it also can guarantee the perfect product quality.

2. General feature

Our Autoclave is a sealed pressure vessel which can be heated by a forced convection heating unit, where temperature, pressure and vacuum can be controlled effectively. By means of an advanced design, consisting of a forced convection fun and motor unit, output heating power system can be adjusted 0-100%,proportional control of the pressurization, cooling and exhaust components. It can obtain an uniform temperature and pressure according to the process curve. Temperature is check in heating, keeping, and cooling phase. The heating/cooling gradients can be set by operator. Pressure is adjusted in pressurization, keeping, release phase.

2. General Structure

3. Main technical data and price of Composite Autoclave

| 5.1 MODEL#OL-CO0608 COMPOSITE AUTOCLAVE-TECHNICAL PARAMETER | |||

| No. | Description | Unit | Specifications and Parameters |

| 1 | Effective Working Diameter | mm | 600 |

| 2 | Effective Working Length | mm | 800 |

| 3 | Design Pressure | Mpa | 1.6 |

| 4 | Max. Working Pressure | Mpa | 1.5 |

| 5 | Max. Pressurization Rate (average) | bar/min | 0.06 |

| 6 | Max. Depressurization Rate (average) | bar/min | 0.06 |

| 7 | Safety valve exhaust | Mpa | 1.55 |

| 8 | Design Temperature | ℃ | 250 |

| 9 | Max. Working Temperature | ℃ | 240 |

| 10 | Max. Heating Rate(Air average) | ℃/min | 3.0 |

| 11 | Max. Cooling Rate (Air average) | ℃/min | 3.0 |

| 12 | Thermal load during test | Kg | 400kg steel |

| 13 | Temperature uniformity at steady state | ℃ | ±2 |

| 14 | External shell temperature at max. temperature | ℃ | <60 |

| 15 | Quick opening Door Mode | ---- | hydraulic |

| 16 | Working Medium | ---- | Compressed Air |

| 17 | Heating Mode | ---- | Electric(Convection+Radiation ) |

| 18 | Heater | ---- | inconel tubular heaters |

| 19 | Heating Power | KW | 15 |

| 20 | Quantity of Circulating Fan Motor | Set | 1 |

| 21 | Power of Circulating Fan Motor | KW | 2.2 |

| 22 | Thermocouple type | ---- | Type K |

| 23 | Air Temperature Thermocouples | Piece | 2 |

| 24 | Part Temperature Thermocouples | Piece | 8 |

| 25 | Quantity of Pressure Transducer | Piece | 1 |

| 26 | Vacuum Lines | Piece | 8 |

| 27 | Quantity of Vacuum Probe | Piece | 8 |

| 28 | PLC-controlled valves on each vacuum line | --- | Vacuum and Vent |

| 29 | max. Vacuum Pressure | Mpa | -0.098 |

| 30 | Standard Control Mode | --- | PLC+PC |

| 31 | Control Software | --- | Thermal Processing Control (TPC) |

| 33 | Insulation Type | --- | Internal |

| 34 | Insulation Material | --- | Ceramic fiber |

| 35 | Insulation Thickness | mm | 100-150 |

| 36 | Insulation Sheet metal | --- | Stainless Steel |

| 37 | Working environment temperature | ℃ | Min.-20℃,max +45℃ |

| 38 | Working environment humidity | --- | <60% |

| 39 | Power supply | --- | 220/380VAC, 3P+N+PE, 50/60Hz |

| 40 | Weight | Kg | ~1500 |

Product Categories : Composite Autoclave

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.