Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Packaging: nude packing

Transportation: Ocean,Land

Port: SHANGHAI PORT,NANJING PORT,CHANGZHOU PORT

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF

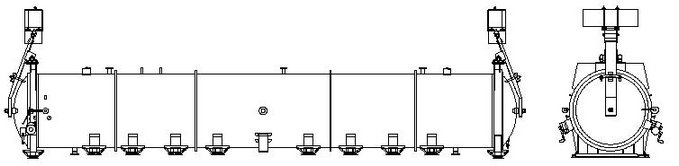

Automatic AAC Autoclave fly ash block

AAC BLOCK MAKING MACHINE AUTOCLAVE INTRODUCTION

Autoclave belongs to pressure vessel which has explosion risk. According to the supervision regulation on safety technology for pressure vessel on divide standard of pressure vessel, the product is part of first and second class pressure vessel. Before putting into operation, the end-user must register in the local boiler and pressure vessel safety supervision organization and acquire the operation permit, at the same time it must accept supervision and inspection.

Specifications:

|

Item | Type | ||||||

| Φ1.65m*L | Φ2m*L | Φ2.5m*L | Φ2.68m*L | Φ2.85m*L | Φ3m*L | Φ3.2m*L | |

| Inner diameter | Ø 1.6m | Ø 2m | Ø 2.5m | Ø 2.68m | Ø 2.85m | Ø 3m | Ø 3.2m |

| Length | L | L | L | L | L | L | L |

| Designed pressure | 1.6Mpa | 1.6Mpa | 1.6Mpa | 1.6Mpa | 1.6Mpa | 1.6Mpa | 1.6Mpa |

| Designed temperature |

204℃ |

204℃ |

204℃ |

204℃ |

204℃ |

204℃ |

204℃ |

| Max operation pressure | 1.5Mpa | 1.5Mpa | 1.5Mpa | 1.5Mpa | 1.5Mpa | 1.5Mpa | 1.5Mpa |

| Max operation temperature | 201℃ | 201℃ | 201℃ | 201℃ | 201℃ | 201℃ | 201℃ |

| Medium | Saturated Steam | ||||||

| Rail distance / height | 600mm/ 150mm | 600mm/ 150mm | 800mm/ 200mm | 800mm/ 250mm | 963mm/ 280mm | 1220mm/320mm | 1220mm/ 320mm |

| Corrosion allowance | 2mm | 2mm | 2mm | 2mm | 2mm | 2mm | 2mm |

Advantages of AAC:

| 1 | Sand | JC/T622-1996 | ||||||

| Excellent goods | First-class goods | Qualified goods | ||||||

| SiO2 | silicon dioxide | ≥ | 85% | 75% | 65% | |||

| K2O+Na2O | kalia+sodium oxide | ≤ | 1.50% | 3.00% | 5.00% | |||

| SO3 | sulfur trioxide | ≤ | 1.00% | 2.00% | ||||

| clay | ≤ | 3.00% | 5.00% | 8.00% | ||||

| water ratio | ≤ | 8.00% | ||||||

| calcium carbonate (coral, sehll, etc.) | ≤ | 10.00% | ||||||

| impurity (bark, grass roots) | N/A | |||||||

| 2 | Flyash | JC409-91 | ||||||

| Excellent goods | First-class goods | Qualified goods | ||||||

| Finess(0.045mm square screen left) | ≤ | 30% | 45% | 55% | ||||

| Water requirement of normal consistency | ≤ | 50% | 58% | 60% | ||||

| loss on ignition | ≤ | 7% | 12% | 15% | ||||

| SiO2 | ≥ | 40% | 40% | 40% | ||||

| SO3 | ≥ | 2% | 2% | 2% | ||||

| 3 | Lime | JC/T621-1996 | ||||||

| Excellent goods | First-class goods | Qualified goods | ||||||

| A(CaO+MgO) | Available calcium | ≥ | 90% | 75% | 0.65 | |||

| MgO | magnesia | ≤ | 2% | 5% | 8% | |||

| SiO2 | silicon dioxide | ≤ | ||||||

| CO2 | carbon dioxide | ≤ | 0.07 | |||||

| degesting speed min | ≤ | 5--15 | ||||||

| degesting temperature ℃ | ≥ | 60--90 | ||||||

| undigested residue | ≤ | 5% | 10% | 0.15 | ||||

| Fineness of finished product (remainder above 0.08mm hole screen) | ≤ | 10% | 15% | 0.2 | ||||

| 4 | Cement | GB175-1999 | ||||||

| Chemical composition | ||||||||

| SiO2 | silicon dioxide | 21-23 % | ||||||

| Al2O3 | aluminium sesquioxide | 5-7 % | ||||||

| Fe2O3 | iron sesquioxide | 3-5 % | ||||||

| CaO | calcium oxide | 64-48 % | ||||||

| MgO | magnesia | 4-5 % | ||||||

| 5 | Aluminium powder | JC407-2000 | ||||||

| Type | Code | Solids content | activated aluminium in solids | Foaming rate (%) | ||||

| ≥ | ≥ | 4min | 16min | 30min | ||||

| Oil-based formulation | GLY-75 | 75% | 90% | 50-80% | 90% | 99% | ||

| GLY-65 | 65% | |||||||

| Water-based formulation | GLS-70 | 70% | 85% | |||||

Product Categories : AAC Autoclave

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.